Reneos: the European tailor-made solution for end-of-life batteries

Reneos is a European network specialising in the collection and recycling of batteries, and offering tailor-made solutions. Read more about it here

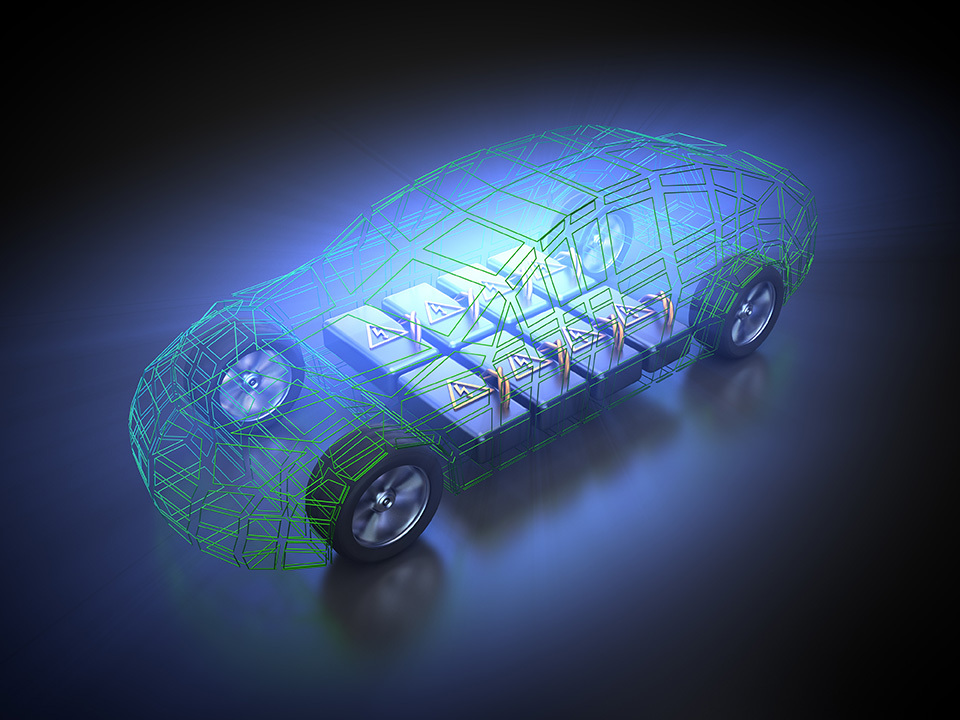

‘How long will the battery last before I need to replace it?’ is a widespread worry for many consumers buying an electric car. But the battery lifespan issue is not just an end user concern. Manufacturers and importers are also anxious to know if the battery will need replacement under the consumer’s warranty. And when EU policy makers incentivise electric driving, their main concern is: ‘how do we prevent these batteries from turning into waste?’. Well, it looks like there is a solution that offers relief for all of these worries: battery repair centres.

What role can battery repair centres play in extending the life cycle of EV batteries? Find out in this article.

Remember the Waste Management Hierarchy? This is a funnel shaped structure we can use as a guide for dealing with discarded batteries. The top of the funnel shows the most desirable solutions (prevention and reuse), and at the bottom we find the action that should be avoided for as long as possible (disposal).

Repair centres offer a solution in the top layers of the hierarchy. By repairing batteries, they are able to extend the lifespan of batteries considerably. They have a team of experienced high-voltage experts, certified to work on lithium-ion batteries.

This is how they operate:

Prevention of battery waste (hierarchy level 1)

The first mission of a repair centre is to repair the failed battery, so it can be placed back in the vehicle, and no replacement is required. This is without a doubt the most cost-effective and sustainable way of dealing with failed batteries.

Battery reuse or recycling (hierarchy level 2 and 3)

If the battery can’t be repaired for continued use in vehicles, there are still options to keep it away from disposal. The repair centre will either send it to a partner company for a second life in non-automotive applications (usually energy storage), or to a recycling company, where the raw materials are reclaimed for manufacturing new EV batteries.

When a lithium-ion battery arrives at the battery repair centre, it usually goes through 3 phases:

(If repair for the electric vehicle is not possible, the battery or module is sent to a partner for remanufacturing or recycling.)

BatteriRetur, Norway’s main battery collector, feels that there is a growing need for battery repair centers. “Often only one of the modules is defective and not the whole battery”, says Per-Magnus Karlsson from BatteriRetur. “In that case you can change one module and the battery will work again.” A common failure in EV batteries is corrosion on parts that can signal an error to the battery management system, which stops the functioning of the vehicle.

It makes sense that the national battery collector, who is at the source, is one of the first companies to take the initiative to build a highly specialised battery repair centre. BatteriRetur already has a lot of the knowhow and expertise to handle batteries, so why not use it to meet a growing need in the EV market? The new repair centre is yet to be launched, but can already count on the collaboration of several car manufacturers and importers.

BatteriRetur: “In the future, car manufacturers themselves will also play a major role in the extension of battery life. Repair centres can have a supporting function, for specialised battery repair.”

It’s clear that battery repair has a lot of advantages for many players involved in the battery game. Extending the life of lithium-ion batteries saves costs for the manufacturer and the importer of electric vehicles, since the battery is an expensive part of the electric car, and is often covered by the manufacturer’s warranty.

Furthermore, the batteries’ extended sustainability is good news for the environment. The longer a battery remains in circulation, the longer it stays out of the bottom layer of the waste management hierarchy (disposal), which helps many European companies meet their sustainability goals.

Repair centres could potentially make a big difference in the life extension of lithium-ion batteries, but only if failed batteries actually find their way to these places. This requires well organised logistics.

Unlike ‘waste’ batteries, batteries that are destined for repair can be freely transported across national borders. This is because they are given the status of ‘product’, not ‘waste’, according to EU norms.

That’s where Reneos can be of assistance. We can help manufacturers and importers of electric vehicles with the logistics of failed and discarded batteries. We can collect and safely transport your batteries all over Europe, thanks to our network of local partners in different countries.